itsTRU® Technology

The power of itsTRU® Technology

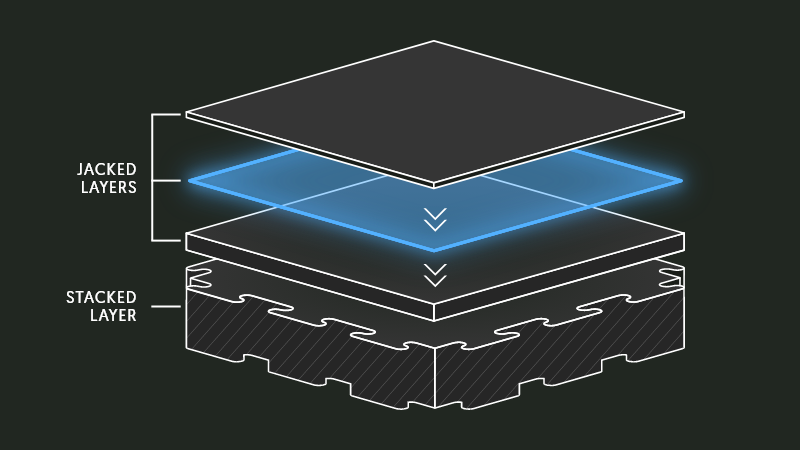

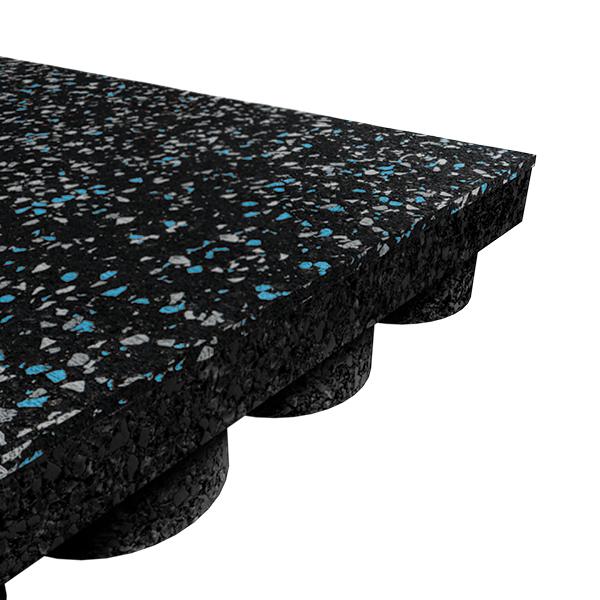

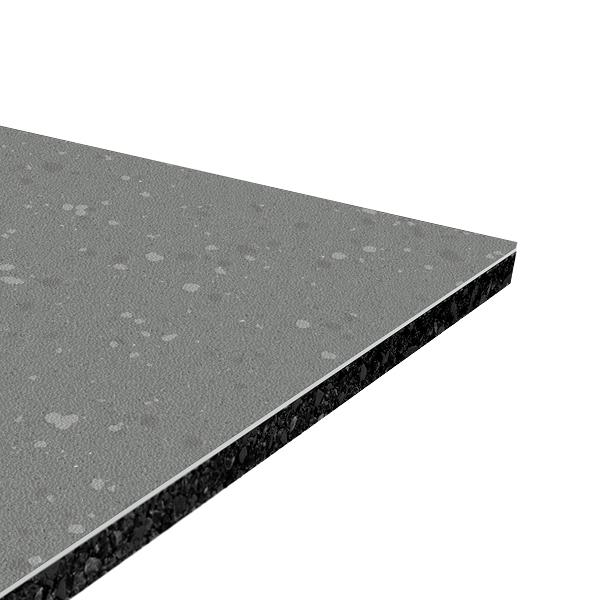

Vulcanized composition rubber (VCR) is a powerful performance material that's good for the planet, but adhering it to flooring surfaces like turf or vinyl has always been a challenge in our industry—until now. After years of research and experimentation, we discovered an effective way to fusion-bond VCR to virtually any surface, using an innovative pressurized process that develops and captures energy. We call this the NRG Factor: a surface's ability to absorb force while returning usable energy back to the body.

What is itsTRU® Technology?

See how our patented technology enables us to create floors that do more.

Watch the Video

Markets

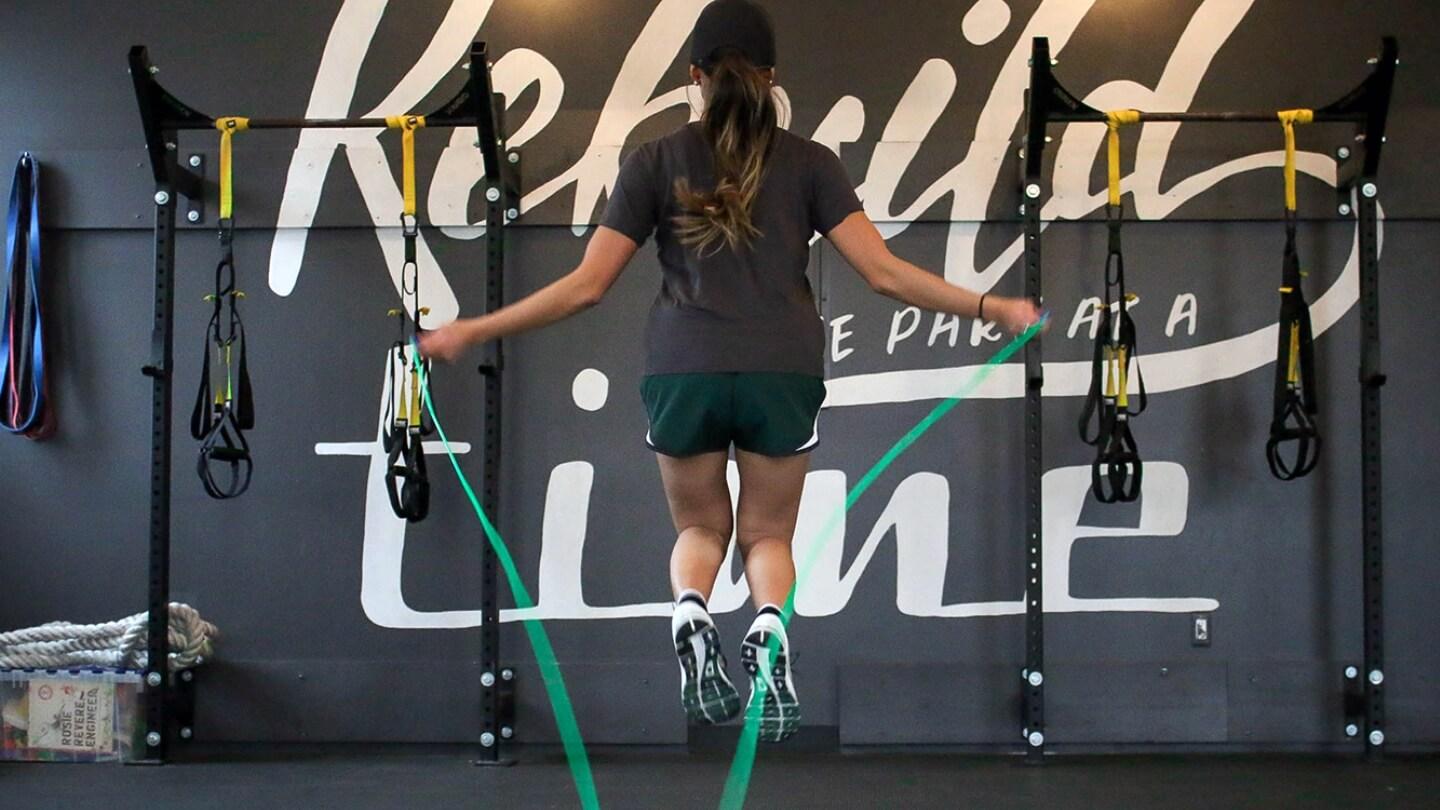

When selecting flooring for a fitness, physical therapy or other wellness setting, choosing the right surface is critical to the success of those who use it. Ecore's high-performance flooring options offer unique combinations of benefits for every application—making it the ideal choice across markets.

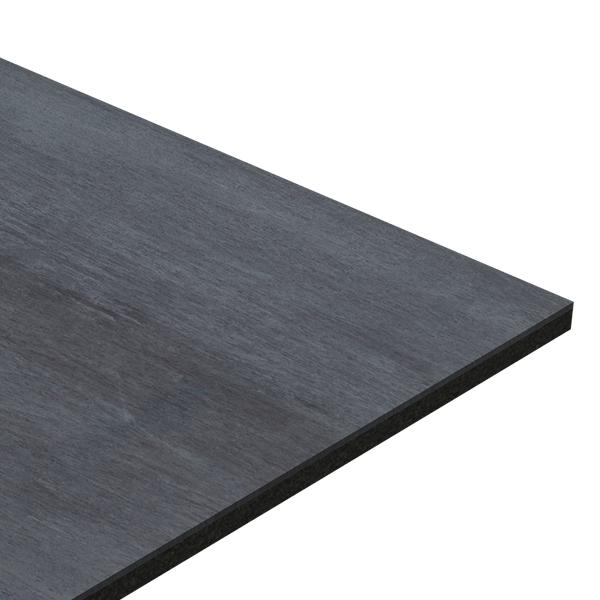

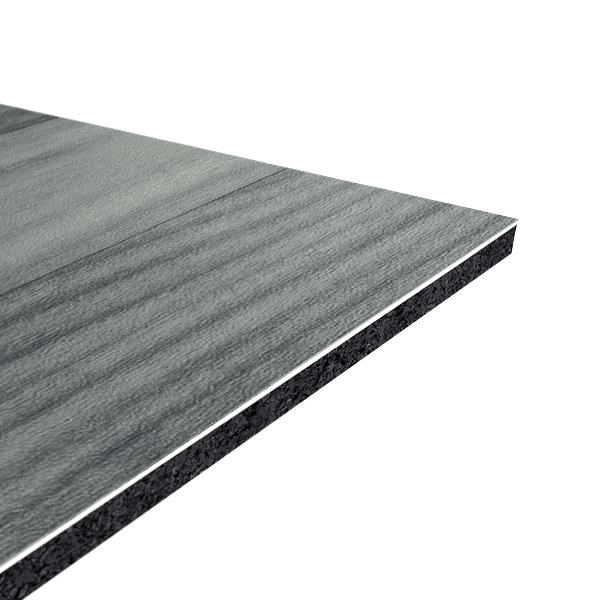

Featured Products

Browse Ecore's newest releases and most popular rubber flooring products.